The production of biogas using a wet process has increased significantly in Italy in recent years; in fact, over a thousand plants have been built based around this low-cost technology with highly flexible processes. Those investing in such infrastructures can enjoy numerous advantages:

In general, it can be said that these systems ensure lower management costs while at the same time minimising operating costs. They are stable systems that produce high-quality compost, which must nonetheless be subjected to a precise protocol to establish its benchmark characteristics.

In 2006, a medium-sized plant opened its doors in the municipality of Lana. This plant makes use of the waste separation systems of over thirty cities to produce energy by means of a wet anaerobic digestion process. The incoming waste is first ground up and homogenised before being mixed with 7 tons of water, reducing the percentage of dry matter down to 4%. Subsequently, the solution thus obtained is passed through a grid that separates heavy materials from light ones, allowing the various impurities to be isolated.

Afterwards, the mass is channelled into a thickener, where the dry matter level reaches 11%. At this point the mass is ready for fermentation and is therefore sent to a digester, where it remains for at least 16 days at a temperature of 37 degrees Celsius.

The digestion process takes place at this temperature, leading to the formation of biogas consisting of 60% methane, which is burned in two co-generators with 334 kW and 536 kW of electric power.

Biogas has applications that offer countless benefits, and our company can help you understand what they are and how to maximise them.

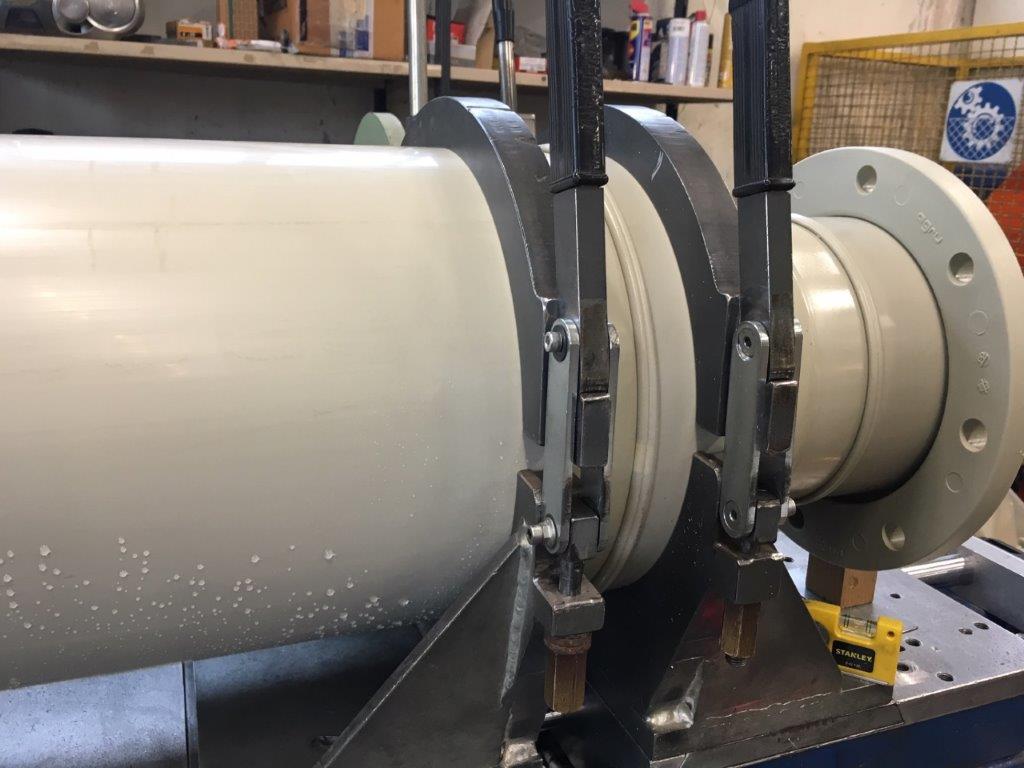

Rariplast produces components for wet process biogas production including:

Contact us!